Paint sprayers use pressurized air to atomize paint, breaking it down into a spray of small particles. This process provides a thin, smooth coat that cannot be achieved through manual paint application. Paint spraying equipment also improves efficiency, as it delivers more paint at once than a brush or roller. Also, due to their reservoir tank, paint sprayers also do not need frequent renewal of paint supply. Read More…

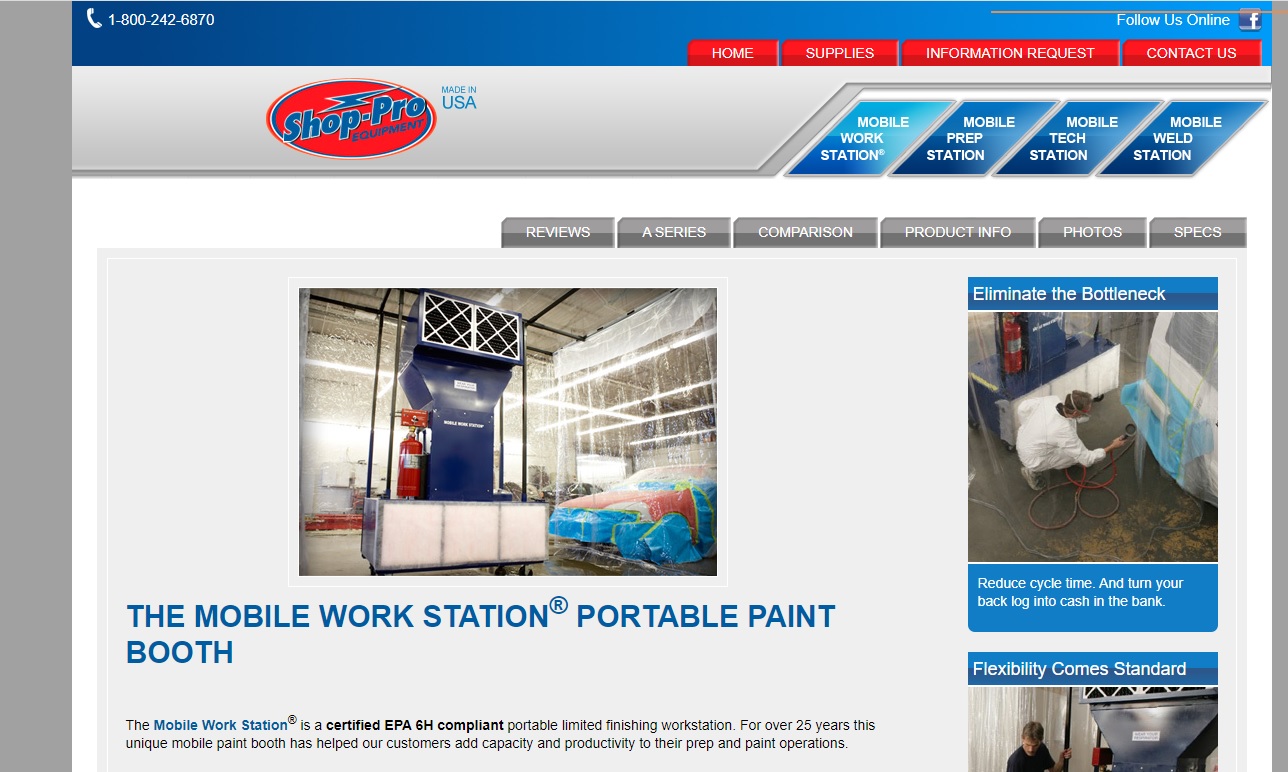

Manufacturer of portable paint booths featuring multi-stage filtration systems to remove paint overspray along with carbon filters to remove odors and VOCs. American-made quality and productivity. Contact us or visit our website to learn more about how we can help you today!

We represent industry leading manufacturers of coatings application equipment. Understanding the importance of your finishing process requirements, our experienced staff of field representatives and industry product specialists, together with our engineering and installation resources, can help maximize your return on investment.

Quality Finishing Systems has been designing and manufacturing state-of-the-art industrial parts washers for over 20 years. Throughout the years, we have strived to perfect our products to continually meet the needs of our customers. Our expert team work alongside customers to ensure their industrial parts washers' needs are met.

Generic Systems is a manufacturer of spray painting robots, finishing systems, spray painting equipment, powder coating equipment and paint sprayers. We provide turnkey systems and reliable, cost-effective design, manufacturing and installation of spray equipment systems. Check out our website for more info.

Our team of dedicated professionals takes great pride in exceeding your expectations for finishing requirements. We specialize in powder coating booths, powder coating job shops, paint stripping and burn-off services, metal finishing equipment and more. Improve the efficiency of your operation and reduce your costs by calling Finishing Systems today!

More Spray Painting Equipment Manufacturers

Industrial jobs often require special painting equipment like spray painting equipment. Spray booths, which are enclosures used in the application of a uniform paint coat, are utilized to limit the exhaust of toxic fumes to designated areas. Spray booths are common in manufacturing plants and in professional workshops.

Paint equipment can drastically vary in size and capability based on the application. These equipment types include paint booths, paint sprayers, paint systems, striping machines, airless paint sprayers, automated paint finishing equipment, electrocstatic painting, hardcoat systems, powder coating equipment and more.

Spray booths are a type of spray painting equipment used for the application of paint, powder, and thermal coating. Spray booths can have special features that allow for the recollection and reuse of paint. These enclosures come in a variety of designs, from small cabinets to entire rooms that can accommodate the machine operator in addition to the items being coated.

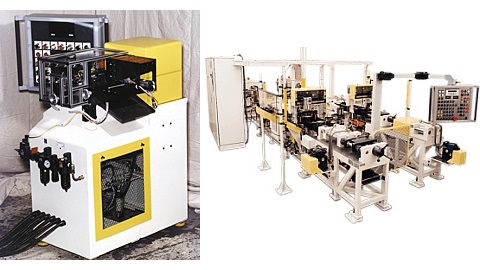

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

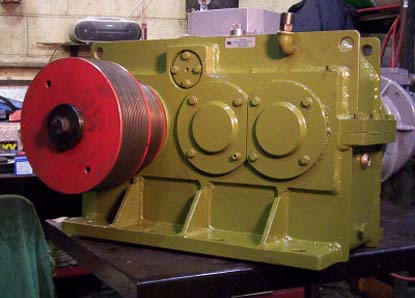

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services