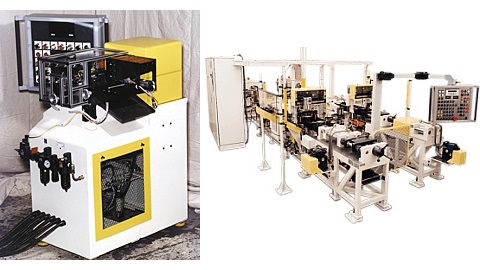

Paint booths either have an open front (without walls or doors in the front of the booth) or are completely enclosed (all sides have walls or doors). Paint booths are available as standalone units or as a component of conveyorized finishing systems. The primary usage of a paint booth is to confine paint overspray, protecting both the environment and staff. Read More…

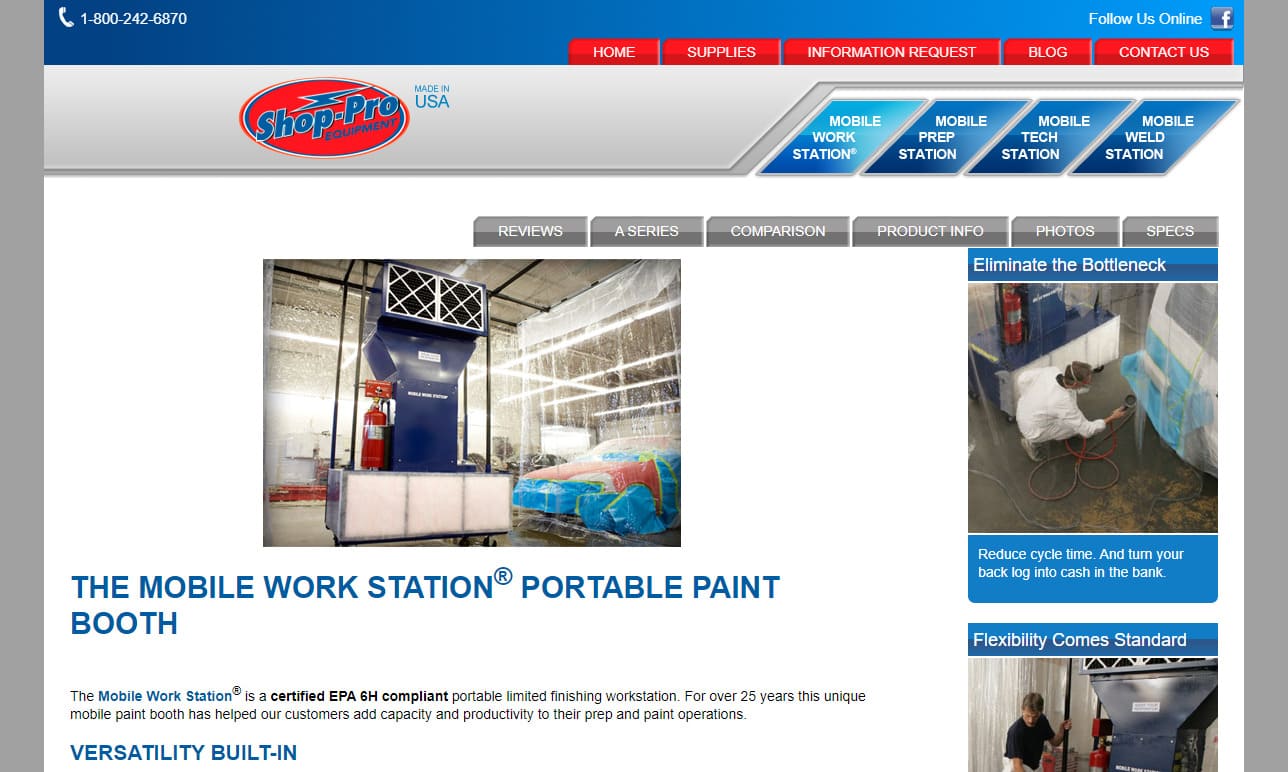

Manufacturer of portable paint booths featuring multi-stage filtration systems to remove paint overspray along with carbon filters to remove odors and VOCs. American-made quality and productivity. Contact us or visit our website to learn more about how we can help you today!

Developing quality systems of the highest life cycle value for over 50 years, KOCH is the choice for over 1,200 manufacturers in nearly 40 countries. We are a world leader in the design, construction, and installation of paint finishing equipment and we offer each customer the most up-to-date, efficient and reliable options for their quality, cost and space requirements. Let us serve you today!

Quality Finishing Systems has been designing and manufacturing state-of-the-art industrial parts washers for over 20 years. Throughout the years, we have strived to perfect our products to continually meet the needs of our customers. Our expert team work alongside customers to ensure their industrial parts washers' needs are met.

Garmat® USA, Inc. paint mixing rooms are designed to provide a well-illuminated, clean ventilated work area for mixing applications. These units utilize a positive pressure environment to help eliminate contaminated shop air from interfering with the mixing process. The Garmat USA paint mixing room is a key element when considering your paint shop requirements.

Obtaining top-notch paint finishing equipment, finishing systems, paint sprayers, spray booths, filters and other related items is one of the things Southern Fluid Systems does. Fluid- and air-handling equipment are our specialty. In business since 1971, we also have knowledge of government regulations.

More Portable Paint Booth Manufacturers

A specially made enclosure called a portable spray booth (also known as a desktop paint booth or ductless spray booth) is used to contain fumes and vapors released during the application of epoxy or paint. In addition, portable spray booths create a safe breathing area for the operator by removing dangerous gasses from the direct vicinity.

Functioning of a Portable Paint Booth

Below is a step-by-step explanation of how a generic portable paint booth works:

- The user paints various items under the hood. This process produces overspray, which the fan then transports into the filtration system along with outside air.

- Most overspray is caught and eliminated from the airflow as the air goes through the internal Spray Pre-Filter Rack inside the hood.

- The filter collects the leftover spray particles and aerosols that the pre-filter didn't remove.

- The activated carbon filter, the last stage of filtration, eliminates any volatile organic compounds (VOCs) and solvent vapors in the airstream before releasing the cleaned air back into the room.

Safety Considerations of Portable Paint Booth

Even though a portable paint booth has a lot of benefits over the immobile paint booth, there are still some safety considerations one should adopt during the installation process of a portable paint booth. Here are some of the paramount safety considerations:

Protection of Air Quality

The primers, varnishes, and finishing compounds used in the portable paint booth, whether intended for wood finishing or automotive painting, include toxic chemicals that might harm equipment or have negative health effects. In numerous ways, a properly operating paint booth lessens the danger posed by these chemicals:

- Establishing a closed environment for the finishing process

- Catching overspray before the booth's air supply runs out

- Supplying makeup air to keep the booth and shop's air pressure balanced

- Heating the air to hasten the curing of the finishes

Reducing the Fire Risk

Given that most finishing products are very flammable, it is crucial to take precautions to reduce the risk of a fire. An ignition source, oxygen, and flammable material are the three elements that might result in an explosion or fire. During normal portable paint booth operation, liquid finishing ingredients are transformed into airborne particles, which then gather on tools and in overspray filters. Since it is impossible to exclude oxygen from the air within and around the paint booth, the final element, the ignition source, must be carefully managed.

Safe Storage for Mixing

Paints, varnishes, solvents, and other flammable substances must be handled and stored securely. During all stages of operation, such as mixing, transferring, and applying finishes, staff members should wear the appropriate protective gear.

Preventive Maintenance

The following are a spray booth's preventative maintenance instructions:

- Change intake and exhaust air filters as often as the manufacturer advises.

- Maintain all hoses, fans, and other machinery in a clean, overspray- and debris-free condition.

- Regularly inspect the ducting and seals, and fix any leaks.

- Execute any upkeep instructions provided by the manufacturer.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

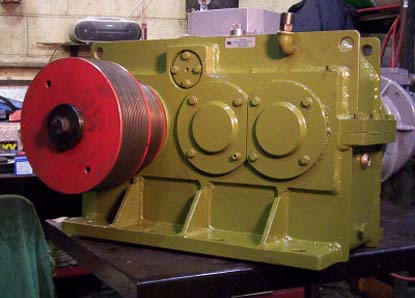

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services