The term paint finishing encompasses the entire range of processes engaged in the application of paint or finishes to a surface. These processes use all kinds of machines and tools (broadly called paint finishing equipment) to apply finishes for two basic purposes, functionality and aesthetics. Read More…

Manufacturer of portable paint booths featuring multi-stage filtration systems to remove paint overspray along with carbon filters to remove odors and VOCs. American-made quality and productivity. Contact us or visit our website to learn more about how we can help you today!

We represent industry leading manufacturers of coatings application equipment. Understanding the importance of your finishing process requirements, our experienced staff of field representatives and industry product specialists, together with our engineering and installation resources, can help maximize your return on investment.

Quality Finishing Systems has been designing and manufacturing state-of-the-art industrial parts washers for over 20 years. Throughout the years, we have strived to perfect our products to continually meet the needs of our customers. Our expert team work alongside customers to ensure their industrial parts washers' needs are met.

Generic Systems is a manufacturer of spray painting robots, finishing systems, spray painting equipment, powder coating equipment and paint sprayers. We provide turnkey systems and reliable, cost-effective design, manufacturing and installation of spray equipment systems. Check out our website for more info.

Our team of dedicated professionals takes great pride in exceeding your expectations for finishing requirements. We specialize in powder coating booths, powder coating job shops, paint stripping and burn-off services, metal finishing equipment and more. Improve the efficiency of your operation and reduce your costs by calling Finishing Systems today!

More Paint Finishing Equipment Manufacturers

Finishing coats are almost always used to provide surfaces with one or more layers of protection against chemical agents and environmental impact. The singular term paint finish is sometimes equated with the term paint sheen – which, in turn, simply refers to how glossy a paint is. Glossiness is specifically a measure of a surface’s ability to reflect light. Typically, paint finishes have a dual purpose of enhancing (or mitigating) this aspect of a surface’s visual appearance.

The specific topic of paint finishes is, obviously, an important facet under the umbrella of “paint finishing” as a whole. However, since industrial paintings and coatings have been treated in a separate article, the remainder of this article will focus on the actual processes and tools that apply such coatings for the purposes described above.

The applications of paint finishing equipment range from at-home projects (e.g. the painting of one’s house) to large manufacturing ventures that require automated or robotic paint finishing equipment. Paint finishing is crucial to a broad range of industries, including construction/architecture, food, pharmaceuticals, manufacturing, glass, paper, and timber. A small sample of commercial products which normally undergo paint finishing includes containers of various types, electronic equipment or components, metal forms and metallic components, paperboard products, ceramic or porcelain objects, and various wooden products.

Manufacturing, in particular, is one of the most common applications of paint finishing. Entire paint finishing systems are often designed for use by original equipment manufacturers, or OEMs. While the metal field is the fastest-growing manufacturing sector for paint finishing, the furniture industry is currently the largest sector. Interestingly, neither of these two sub-fields are responsible for the main growth in paint finishing. Currently, the architectural market is the strongest commercial sector for paint finishing growth in general.

Applications

In order to better understand the range of paint finishing equipment, it is necessary to first obtain some basic knowledge of the overall paint finishing process. While actual paint finishing processes also vary widely, many of them can be broken down into basic steps of pretreatment (usually involving washing), drying, application of paints/coatings, and curing.

Since the actual application of a coating is (arguably) the essence of paint finishing in general, the main focus will be on equipment that specializes in this step.

As was previously mentioned, domestic or other architectural applications constitute a huge portion of the paint finishing market. Tools that often accompany these types of applications include paint rollers, brushes, roller trays, drop cloths, painter’s tape, dip sticks, and sandpaper. These types of tools are usually used to apply paint and paint primer in common, domestic scenarios like wall painting. More advanced, industrial painting projects often employ paint machines, which are automated systems that use conveyors and robots to speed up and streamline the painting process. Some of the most important and distinct types of paint finishing equipment are found in these types of coating systems. One approach to categorizing such equipment revolves around the specific type of paint application method they engage in. Generally, industrial paints or finishes are applied via spraying, dipping, or flow coating.

Spraying is the most common and distinct form of applying industrial paint finishes. Common features of a basic spray painting system configuration include a nozzle, an air compressor, a pressurized paint container, and connecting tubes or hoses. The basic spray-application device is a triggered gun that sprays paint in even, thin coats. It is popularly known as a paint sprayer or spray gun.

Because spraying is so integral to the paint finishing industry, several major types of spraying devices have developed over the years. They are often distinguished by how they atomize the paint being applied (e.g. via compressed air, via hydraulic pumps, etc.)

The most conventional air guns are air-atomized spray guns which use compressed air to break up moving, liquid paint into spray. This atomization can occur either internally or externally.

Like all spray guns, air-atomized spray devices depend on a pump to generate a liquid paint stream.

Airless paint sprayers produce a fine mist of paint in a slightly different way than an air-atomized spray gun. Instead of using an air compressor, airless paint sprayers rely on tremendous internal pressure and momentum to break paint into droplets as it emerges from a tiny orifice in the spray gun. These devices are valued in chemical, marine, and industrial applications, where they apply coats of paint extremely evenly and with a level of wetness that ensures superior adhesion, flow-out, and penetration of pits and crevices.

Air-assisted airless spray guns constitute a “hybrid” version of the previous two devices. They depend on small orifices and compressed air to atomize moving liquid paint. The devices are well suited for scenarios requiring elevated fluid pressure and elevated temperatures to atomize highly viscous paints.

High volume low pressure (HVLP) paint sprayers use compressed air to atomize paint in a similar fashion to air-atomized devices. They are intentionally designed to apply paint at low pressure in order to reduce droplet velocity and overspray or blowback associated with high velocities. (Originally, HVLP sprayers also relied heavily on heated air to lessen cooling and condensation associated with air-atomized and airless device.)

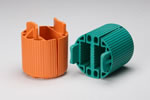

A significant type of finishing equipment is electrostatic painting equipment (also called powder coating equipment). This category of equipment facilitates a special kind of spray painting that works with electrically charged powder in place of liquid paint. In electrostatic painting, both the powder and the product are electrically charged. This ensures that the powder, (which is charged by contact with an electrode) will be strongly attracted to the metal surface of the product once it is sprayed. Electrostatic spraying is often combined with features of other types of spray painting, such as in air-atomized electrostatic spraying (which depends on compressed air and electricity) and air-assisted airless electrostatic spraying (which depends on compressed air, a small orifice, and electricity).

Spray painting systems, in particular, are valued for the superior quality of the finish they leave, as well as the efficiency they generate by applying paint faster and wasting less paint than rolling or brushing systems. The main disadvantage of such systems lies in the environmental hazards they pose (due to overspray and other forms of contamination). To improve the relationship between the environment and paint finishing, scientists and engineers are developing new alternatives to traditional paints and solvents, which threaten the environment and contaminate water supplies when disposed.

Dipping constitutes the second major category of paint finishing application. As its label suggests, this category of paint application consists of various forms of immersion followed by controlled draining and drying/curing steps. Tanks are some of the most fundamental pieces of paint finishing equipment in the dipping process.

Flow coating forms a third, “hybrid” category between spraying and dipping. It hinges on the use of a pressurized paint reservoir, which pumps paint through connective tubing onto the upper services of products in order for the paint to “overflow” and saturate the product.

In addition to these generalized paint finishing tools and machines, manufacturers produce some paint finishing equipment that is very application specific. A good example of a specialized paint finishing device is the striping machine, which exists to paint lines. Striping machines supply lines in parking lots, on roads, on airport runways, and on the dirt and grass of playing fields. Like most paint finishing equipment, striping machines consist of an air compressor, a spray nozzle, a small engine, and a series of hoses and valves. Another example of specialized paint application can be found in the process of roller coating. In this method, huge industrial rollers apply paint to flat or coiled metal as it passes underneath. The terms direct roller coating and reverse roller coating refer to whether the substrate is moving in the same or opposite direction as the resilient roller (respectively). Coil coating refers to the practice of roller coating on continuous metal strips.

Other Types

Even though the actual step of applying paint is undoubtedly critical, preceding and following steps in the overall paint finishing process should not be overlooked.

Before paint can be properly applied, it needs to be properly prepared. Such preparation often involves mixing to bring the paint to an applicable state. The paint mixer is a machine commonly used with small-scale painting projects; it mixes the contents of a sealed can of paint by rotating, spinning, inverting, shaking, and rocking it at high speeds. A more advanced form of paint mixing utilizes multi-component spraying equipment meters, which sprays paint (using multiple supply pumps) in addition to mixing it beforehand.

In industrial scenarios, conveyors are critical for enabling efficient and controllable paint application. Different conveyor systems exist for different types of painting (e.g. for powder coating, for dipping) and different types of products (e.g. towline conveyors for wood products). Horseshoe-shaped conveyors are often used in conjunction with rotating electrostatic disks, which are unique types of paint finishing equipment that combine centrifugal force with electrostatic painting. Overhead conveyors are the most popular type of conveyor systems.

A variety of different curing ovens are available for the final step of the paint finishing process. Generally speaking, these convection ovens feature an enclosure (or shell), a heater unit, a supply air system, a recirculating air system, and an exhaust air system. At the end of paint application, coated products are typically heated in a curing oven for at least a half-hour.

Since paint finishing is so broad, it can involve a host of “accessory” pieces not directly involved in the actual paint application process. A single example of such a piece is the paint booth. A paint booth is a portable structure designed to both contain potentially hazardous paint fumes and overspray, and to keep out contaminants like dust that could ruin a smooth application of paint. Paint booths, sometimes called spray booths, are available in a variety of designs, from small cabinets to entire rooms. Yet other “accessory” piece in paint finishing include control consoles, dust collectors, hoppers, waste water treatment equipment, and more.

Considerations

Due to the broadness and complexity of paint finishing, it is not possible to discuss every factor that should go into formulating and executing a paint finishing application. Some of the most critical aspects, however, can be briefly surveyed.

Naturally, the actual paint being applied needs to be carefully assessed in any finishing operation. In recent years, paints, stains, finishes, and other coatings have seen great strides in improving chemically (e.g. exhibiting greater viscosity and molecule cohesion) and improving in efficiency (e.g. decreased drying times). A prudent paint finisher should be educated on and aware of the range of coatings now available. To use one illustration, dipping methods of paint finishing suffer from fire hazard and reflux problems. Waterborne paints have proven to be an excellent alternative that eliminates such difficulties.

Paint finishing equipment also needs be carefully assessed in any application. The different aspects of paint finishing are heavily intertwined with all of its other aspects, and this is especially true with regard to paint finishing equipment. Any equipment chosen will be heavily dependent upon the type of paint and method in use. At the same time, equipment itself will be a determining factor in the choice of paint and its particular application method. A hypothetical scenario involving a unique conveyor can illustrate this point. If one uses a certain conveyor system with a uniquely small radius (e.g. 9 inches), then there is greater freedom to reduce the size of other paint finishing equipment (such as ovens, spray booths, etc.). Thus, choosing a compact or space-efficient conveyor can cause a positive domino effect that conserves space and cost throughout the entire paint finishing operation.

Before committing to any specific paint spraying method, it is imperative to weigh its main advantages and disadvantages against each other. For example, electrostatic spraying is a prudent application choice for tubular products, since charged particles tend to “wrap around” and completely saturate objects. At the same time, this effect leads to concentrated film buildup on edges and lower film density inside recesses (due to increased and decreased electrostatic attraction, respectively). Thus, depending on the size and shape of products to be coated, it may or may not be economical to utilize electrostatic spraying.

Perhaps the most important consideration in choosing a paint finishing supplier is taking into account the reality that specialization marks paint finishing (even more so than other industries). It is not uncommon at all to find manufacturers or companies that narrowly focus on a few aspects or even one aspect of paint finishing (e.g. electrostatic coating, fluidized bed systems, flow coating, etc.) This situation can actually be turned to a paint finisher’s advantage in many cases. For example, it may be more economical over the long run to outsource a coil coating process (which requires significant capital investment) to metal producers or private companies that specialize in this process. In addition to standard considerations when looking for a supplier (e.g. range of products, customer responsiveness, depth of expertise, etc.), look for suppliers that provide secondary services that may not technically fall under the rubric of “paint finishing” (e.g. thermal cleaning, degreasing, coating removal, etc.) Furthermore, make sure you understand how a supplier defines and approaches key jargon within the paint finishing industry. To give one example, transfer efficiency (TE) is a very important measure of the quality of many paint finishing pieces. Ironically, though, not all manufacturers calculate it according to the same industry standards.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services